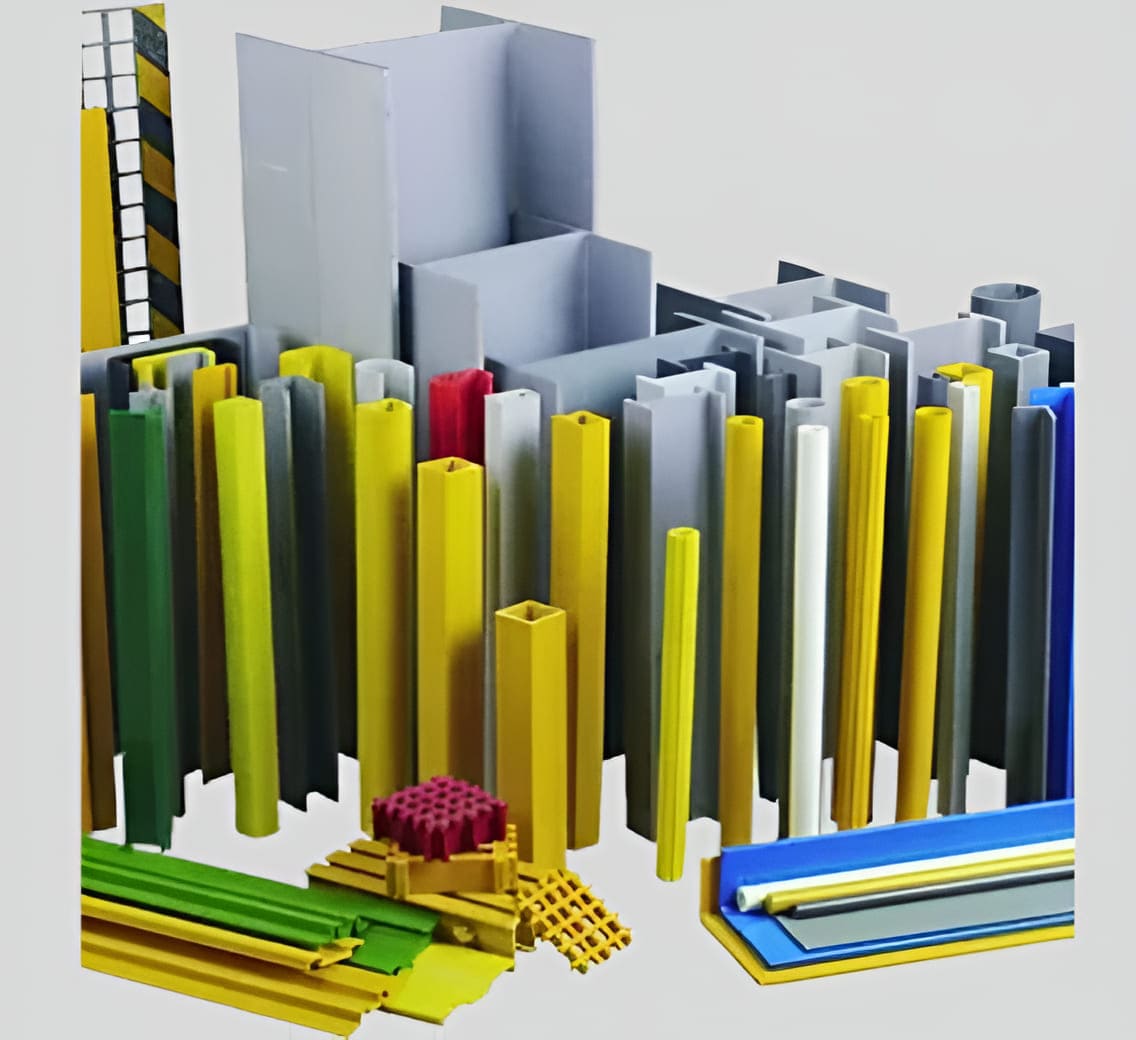

Pultrusion Resin is a specially formulated composite resin used in the pultrusion manufacturing process, where continuous strands of reinforcement fibers like glass, carbon, or aramid are pulled through a resin bath and then cured under heat and pressure. This process results in strong, lightweight, and corrosion-resistant profiles such as rods, beams, and angles, which are widely used in various industrial sectors.

These resins are engineered for optimal fiber wet-out, smooth flow, and consistent curing. Their properties ensure excellent fiber bonding, durability, and environmental resistance, making pultrusion resins suitable for structural applications in harsh conditions. They can be customized using different base types, such as polyester, vinyl ester, or epoxy resins, depending on strength, flexibility, and chemical resistance needs.

Pultrusion Resin is a specialized thermosetting resin system designed for use in the pultrusion process, which involves pulling continuous fibers through a resin bath and then shaping and curing them to form strong, lightweight composite profiles. These resins are formulated to ensure excellent impregnation of reinforcement fibers such as fiberglass, carbon fiber, or aramid fibers, and provide superior bonding, curing, and mechanical performance. Pultrusion resins are crucial in producing structural components that offer long-term durability, chemical resistance, and thermal stability for demanding applications.

They are typically based on polyester, vinyl ester, or epoxy chemistries, and are selected depending on the required performance such as strength, corrosion resistance, or flame retardancy. The resin ensures uniform consistency during the pultrusion process and contributes to the final product’s strength, dimensional accuracy, and surface finish.